Why standardize know-how to boost productivity?

Within an organization, sites and teams with similar activities often perform unevenly, despite efforts to standardize processes, organizations, machines and tools.

The real problem lies in the expertise of the people and teams involved, which varies from site to site. The know-how contains all your experts’ experience in the field, best practices, tips and key points for carrying out operations to meet your quality, safety, efficiency and standards requirements. This quantity of intangible, non-digital information is a major asset, but one that is difficult to capitalize on.

All sectors are impacted: factories, stores, warehouses, production sites, logistics, R&D, public establishments, healthcare…

There has been no solution until now for capturing and disseminating experience methodically, rapidly and on a large scale.

Here are the problems we hear about:

Inefficient transmission

The movement of experts between sites and learning expeditions do not solve this profound and urgent problem. It’s an illusion to hope that learning will cascade and be passed on naturally to teams via a few ambassadors, without having a suitable method or technology.

Tutoring cannot follow

Your experts and instructors can’t tutor all your newcomers, from the moment they arrive until they’ve absorbed all the know-how. Your transmission needs require digital speed. What’s more, these key people often have an operational role to play.

A growing problem

Site openings, relocations, re-industrialization, peaks in activity, staff movements, reorganization, product launches, new machines, changes in operating rates, new standards, multi-skilling of employees… There’s no shortage of situations.

A question of performance

Doing more with less? Recruiting more is not always the answer. Companies have the opportunity to become more efficient by deploying their best know-how everywhere.

The Uptale solution

Transfer know-how without limits to replicate productivity

1. Capturing know-how in high fidelity

- Digitize the know-how of your experts, in situ, in your field

- Shoot in 360° and from the operator’s point of view, with his voice and gestures

- Absorb the practices of your site, your teams, or your key professions

- Capture the environment: workspace, ambient sound, pace, risks…

- Upload your procedures, videos, existing media…

- Compatible with all cameras on the market

2. Create immersive learning modules

- Transform captures into interactive, spatial and immersive modules

- Add pedagogy: quizzes, gamification, conditional courses, scripting…

- Organize your modules into courses, by trade, by workstation, by sequence of operations, by team

- Create autonomously, by your field or learning teams

- Use Uptale models to boost efficiency

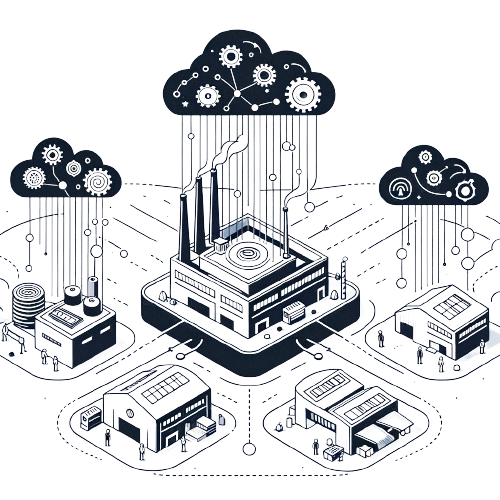

3. Deploy to all sites

- Integrate modules into your business processes: recruitment, onboarding, induction, continuous training, product or machine user guides, etc.

- Train employees with the most effective formats, where they are

- Easily install and manage a fleet of Mixed Reality headsets (VR and AR)

- Manage content and access remotely

- Update and redeploy at any time, with a single click

- Analyze training data

Uptale benefits

Unique know-how capture

Complete, high-fidelity capture of your experts' know-how in the field.

Next-generation learning

All the power of Immersive and Spatial Learning, ideal for upgrading the skills of front-line workers.

Speed and autonomy

No-code platform for controlled installation and maintenance, with minimal effort.

Flexibility and scalability

Modern cloud-native architecture for scalable, secure deployment.

How do companies use Uptale?

DS Smith - Deploying New Machines

DS Smith has similar industrial machines at several sites around the world, and uses the Uptale solution to capture operating procedures with a few experts in the UK for distribution to other countries.

Michelin - Capturing a site's excellence

Instead of regularly sending its community of quality experts to a center of excellence in Eastern Europe, Michelin has digitized this know-how and integrated it into its global quality training programs.

Stellantis - Opening similar sites

Stellantis copied the know-how of an entire vehicle assembly line from one site in Morocco and transferred it to 2 sites which were to produce the same vehicle model. What's more, the transfer between day and night shifts has also raised the performance of the initial site.